Class A Evaporation Pan

Class A Evaporation Pan with Automatic Sensing Refill Kit and Bird Guard

Class A Evaporation Pan with Automatic Sensing Refill Kit and Bird Guard

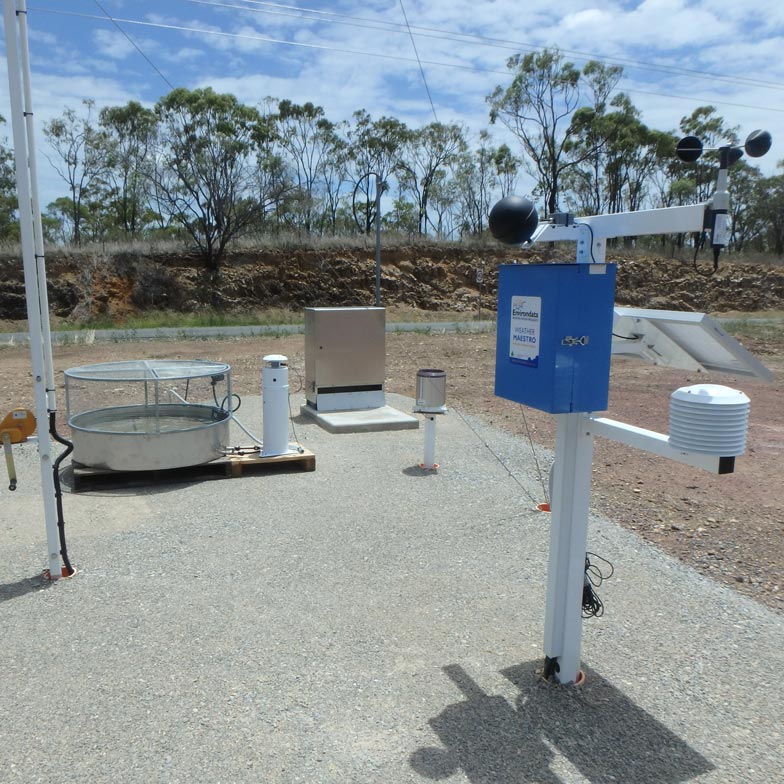

Class A Evaporation Pan with Water Storage Weather Station NSW

Class A Evaporation Pan with Water Storage Weather Station NSW

A number of industries in Australia, and across the world, rely heavily on the evaporation of water. In mining industries, it is often a crucial part of water management including the management of settling ponds and tailings facilities.

Other extractive industries, such as POTASH, rely on the data to model and monitor the effectiveness of evaporation ponds.

Still other industries look to this data as a tool for monitoring the salinity balance requirements, such as in Prawn Farming. While in water storage management, it is a key part of the information required to understand the effect of evaporative loss on the available water supply.

The Class A Evaporation Pan is therefore designed to measure evaporation. Class A means the dimensions of the design meets the standard of the Bureau of Meteorology.

The fauna cage is designed to limit fauna ingress but allow for easy removal and maintenance. Environdata's Class A evaporation Pan is supplied with a highly sensitive water level sensor and an automatic refill system. A timer and float valve allow water from an external source to automatically refill the pan every morning.

Features at a Glance

- Built to survive harsh environments

- Stainless steel construction

- Meets Australian Standards

- Designed to limit vegetation and fauna ingress

- Easy to assemble and maintain

- Includes automatic refill system

- Long operating life

Parameters measured

Evaporation Rate

Industry Applications

- Water Supply Management

- Hydrological Research

- Waste-Water Management

- Mining Water Storage

- Evaporative Mineral Collection Industries

Compatible with

- Weather Maestro

Features In Detail

What is a Class A Evaporation Pan?

In simple terms, a Class A Evaporation Pan is a standardised measurement of water loss through Evaporation. With the characteristics of the Pan construction and installation the same between sites, the resulting observed evaporation is able to be compared across sites with a measure of confidence.

The Class A Pan itself is a low, wide steel cylinder or 'Pan', with an internal diameter of 120.7cm and a depth of 25cm. The pan is filled to 20.0cm deep each morning at 9am. The depth of water the following morning prior to refill represents the evaporative loss.

Of course, this presumes there is no precipitation, or water loss through other means such as stock or wildlife drinking from the pan, hence the pan does need to have a tipping bucket rain gauge nearby to offset incoming precipitation and a mesh guard to prevent loss through drinking by local fauna.

Since the Class A Pan has been accepted as a standard method of measuring Evaporation throughout the USA, Australia and many other countries, data is available to compare across a wide region, further aiding you to model your own evaporation data and tune it to your site's needs.

Class A Pan Evaporation Vs Penman Evapotranspiration Vs Lake Evaporation

Evaporation occurs when the water at the surface of a body of water reaches it's gaseous state (water vapour) and is held suspended in the air.

Several key weather variables influence this process, noteably: Air temperature, relative humidity, wind speed and the net solar radiation absorbed by the body.

- If the air temperature is high, there is more energy present to convert liquid water to water vapour.

- If the relative humidity is low, the air mass can more readily suspend more water vapour, hence the energy required to evaporate is less.

- If the incoming solar radiation & subsequent energy imparted to the body of water (not reflected) is high, again more energy is provided into the system to aid in the transition to water vapour.

- If the Wind Speed is high, then the air mass at the boundary layer is replaced with air not laden with water vapour (drier) hence more readily able to accept moisture.

Pan Evaporation combines these into one device to empirically measure the evaporation of water from a fixed, known water body, the 'Pan'.

Lake Evaporation has no metal sides, deeper water & can be less exposed to wind along shorelines and more exposed in the middle of the water body, and is often 20 to 25% lower than the measured Pan Evaporation. Several methods exist to calculate this, often modified Penman equations, and some involving detailed modelling of the 'lake' of concern, however the key weather variables mentioned are still the key inputs.

Penman Evapotranspiration is calculated from weather data collected locally, and represents the water loss of plants from their surface, as they transpire. Different crop coefficients allow the different evapotranspiration behaviour of crops to be calculated as per the comprehensive United Nations Food and Agriculture publication FAO56. As this is a uniform method of calculating evaporation without the requirement for a Pan, it is often used as a substitute Evaporation Rate calculation. Several studies have proven the correlation to be accurate.

It must be remembered that there will be differences between the methods used at your site. The surrounding terrain, trees, vegetation, buildings and other factors such as surface roughness will have an impact directly on the weather measured at your chosen location. However the use of the Class A Pan will give you a baseline evaporation data set, vital to confirming your other methods, and understanding the evaporation of your key water infrastructure.

Class A Pan Structure

The Class A Evaporation Pan is traditionally constructed of galvanised steel painted Silver. Environdata's Cass A Pan is constructed from 316 Marine Grade Stainless steel, with a polished surface. The difference in material does not change the data measured, however the Pan has a much longer service life, and is able to be used in saline evaporation studies with a much longer field life.

The Pan is fitted with two inlets at the base of the pan. One of these connects to the water level sensor, and the second one allows simple draining without the need to disconnect the rest of the system. An important factor in considering the maintenance.

The bird / fauna guard frame is constructed from 316 Marine Grade stainless steel and covered with a light galvanised steel mesh to minimise shadowing. The fauna guard is designed to allow easy removal without disturbing the refill kit, for easy maintenance when required.

The Pan is installed on a wooden pallet set on level cleared ground. It is important to allow air to circulate underneath the pan and not allow shade from nearby structures to cover the location of the pan. An ideal site for the Pan ensures the surrounding terrain & structures do not impede airflow or otherwise disturb the key weather input data.

Class A Evaporation Pan and Weather Station at QLD Reservoir

Class A Evaporation Pan and Weather Station at QLD Reservoir

Class A Evaporation Pan and Weather Station at NSW Local Government Reservoir

Class A Evaporation Pan and Weather Station at NSW Local Government Reservoir

Class A Evaporation Pan with Automatic Sensing Refill Kit and Bird Guard

Class A Evaporation Pan with Automatic Sensing Refill Kit and Bird Guard

Premium Equipment & Software

Premium Equipment & Software Australian Made & Supported

Australian Made & Supported Expert Advice & Custom Solutions

Expert Advice & Custom Solutions Australia-wide Installation & Service

Australia-wide Installation & Service Satisfaction Guarantee

Satisfaction Guarantee Email Us

Email Us Call us on 07 4661 4699

Call us on 07 4661 4699 Follow Us

Follow Us